Fusion 360

| Macro | Description | Details |

|---|---|---|

| NoseCones360-1.0.zip | Nose Cone Generator | https://www.davesrocketshop.com/?p=265 |

FreeCAD

| Macro | Description | Details |

|---|---|---|

| Nose Cones.FCMacro | Nose Cone Generator | https://www.davesrocketshop.com/?p=194 |

Your home for High Performance Rocketry

Fusion 360

| Macro | Description | Details |

|---|---|---|

| NoseCones360-1.0.zip | Nose Cone Generator | https://www.davesrocketshop.com/?p=265 |

FreeCAD

| Macro | Description | Details |

|---|---|---|

| Nose Cones.FCMacro | Nose Cone Generator | https://www.davesrocketshop.com/?p=194 |

I’ve had a macro for FreeCAD for a couple of years that simplifies creating nose cones using parameters entered in a dialog. For many hobbyists, Fusion 360 is a more popular platform. Here then is a port of the program designed to run as an add-in to Fusion 360.

It’s easiest to explain installation and use in a video so check it out here:

Part 1 – Installation and Options: https://youtu.be/6wYUXH9TK1g

Part 2 – An example: https://youtu.be/jBtWD9JqQ6Q

Also, Wikipedia has a great entry on nose cone design. https://en.wikipedia.org/wiki/Nose_cone_design

Try it out and let me know how it works for you!

Released under the MIT license.

It’s been a busy time with the 3D printer. In addition to some heavy duty runs printing Saturn V parts, I’ve solved issues on 2 different fronts, resulting in not one but two different blog entries! Check them out here: https://www.davesrocketshop.com/?page_id=148

I’ve made no secret of my printers vibration problem. Subtle ghosting, not easy to track down. But I still want good detail prints, so drop the layer height to 0.1 mm at 10 mm/s.

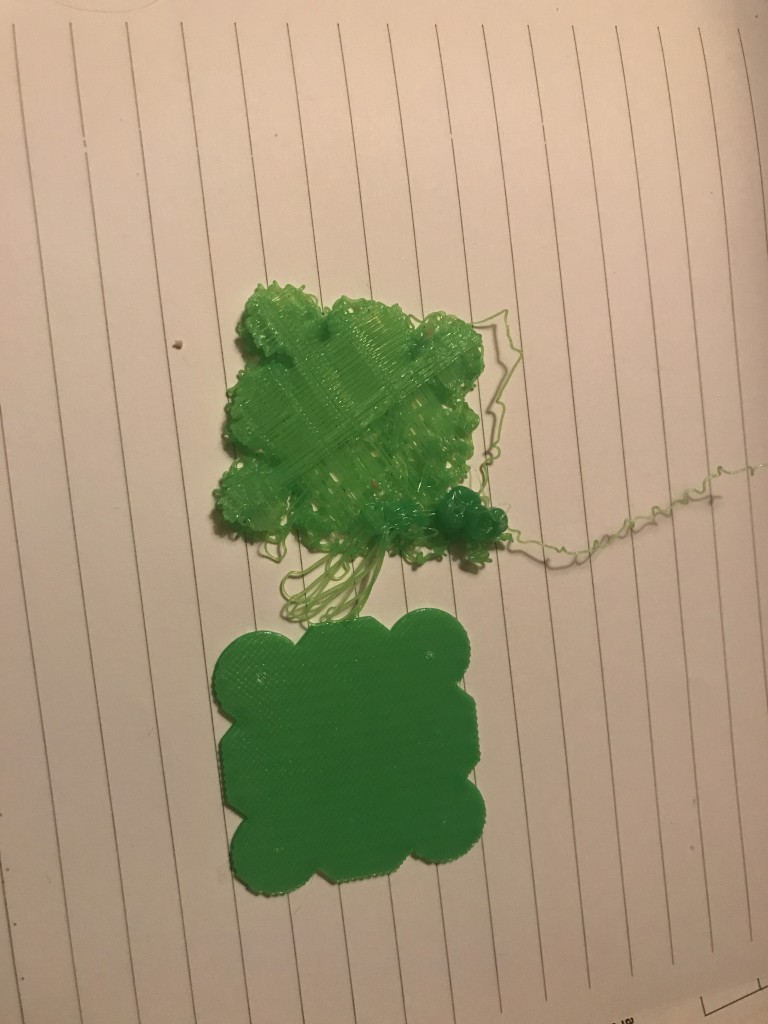

At this speed, the extruder exhibits quantization. The plastic comes out in spurts and under extrudes. The bent string part in the image is the skirt and should be straight. Apparently you can print too slow! I increased the speed to 20 mm/s and the raft prints fine.

Underextrusion caused by extruder quantization

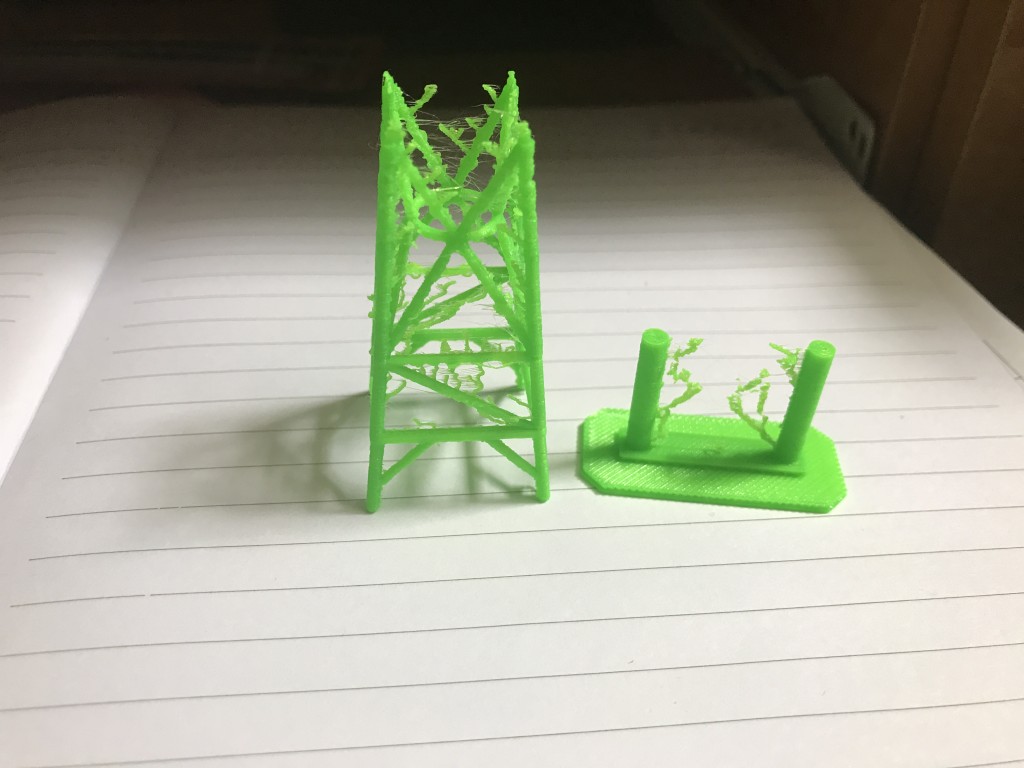

With that issue fixed I print my Saturn V LES tower. Ignore the colour. I’m using a plastic I have lots of for test prints.As I’m fond of saying, for every solution there is a problem, and in this case it’s a bad case of stringing! This is new! A string test confirms it’s probably something in my settings and not inherent in the model.

Stringing in the LES tower confirmed with a stringing test

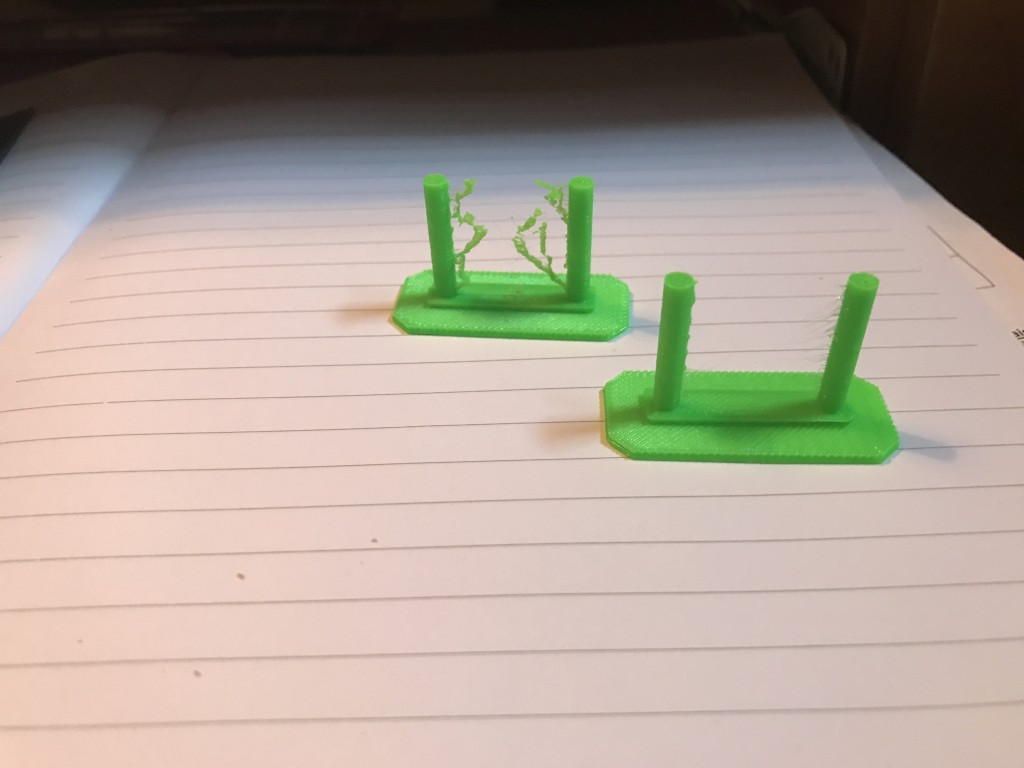

There are many ways to fix stringing. One is to drop the print temperature. I dropped it from 210 down to 195, but with my extrusion heating issues I didn’t dare drop it any more. I increased extrusion distance to 2.5 with no noticeable impact. I increased the retraction speed from 30 to 50 mm/s with some improvement. Finally I retracted 3.5 mm at 80 mm/s. The final result is some small wisps but that’s okay.

Stringing before and after adjustments

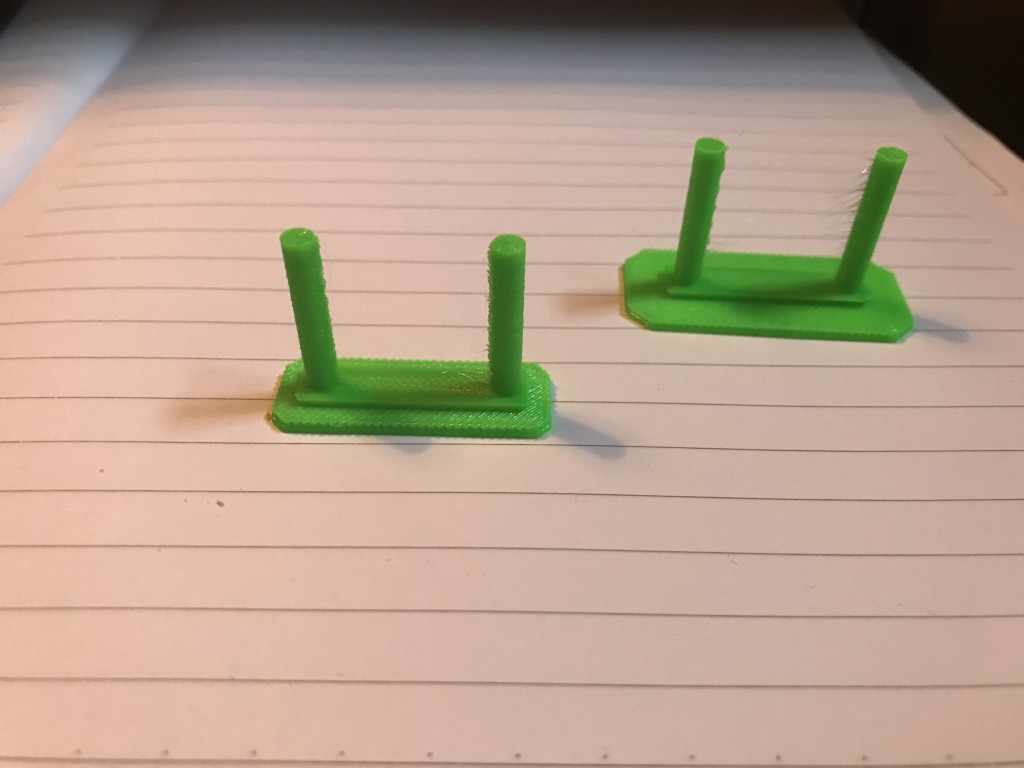

One variable I hadn’t addressed was the filament. This was a new brand for me, and although I’d done a couple of prints already, they weren’t models that would exhibit stringing. A test with my “standard” settings at 40 mm/s and 0.2 layer height show everything is fine. I’m still not sure if it’s the low speed or fine layer height (I suspect the latter), but that’s a topic for another day. For now I have settings that I can use to print, so I’m a happy maker!

Adjusted high detail, low speed string test compared to my normal speed and detail

This does represent a full day of effort. Don’t listen when people say 3D printing is easy. It’s easy for the experts who know all this stuff already, but for n00bs there’s a big learning curve. When I first started this would have set me back weeks! Even now it’s lost time when all I want to do is get something printed.

A few months ago, I upgraded my printer with 2 cooling fans, one on either side of the extruder. Stock configuration had a single fan that got destroyed when an unobserved print went haywire and plastic went into the fan itself. The time was right to do the upgrade.

I can’t remember why, but I updated my firmware at the same time to Marlin 1.1.8, the latest release at the time. I’ve since updated to 1.1.9 but both had the same issues I’m about to talk about. That is thermal runaway protection. The reality is, I’d been affected by this since day one but hadn’t known. The stock fan configuration wasn’t particularly strong, and the software didn’t complain about it, but when my prints started, the fan started cooling the extruder. Close to the bed, at the start of the print, this was quite significant. So much so that the updated software complained that the heater wasn’t able to keep up once the fan turned on, and shut itself off. Every time.

The solution is to use a silicon sock to prevent this by insulating the heater block. I don’t have one. I’m still looking for one that fits.

The workaround is to scale the fans maximum speed back. Way back. It was worse with the new fan configuration, especially near the bed where the cooler air gets reflected back. Depending on the print it will also happen away from the bed. So I turned runaway detection off and babysat the fans so I could maximize print cooling without allowing the extruder temperatures to drop out of acceptable range. That’s a lot of time staring at temperature plots and entering GCode since OctoPrint has no fan control.

Enter Marlin 2.0. It’s not a release version yet although it has experienced significant development already. It will eventually include 32 bit support for a number of boards. But for me the key feature is it automatically scales back the fan speed as the extruder temperature drops. No more babysitting my prints!

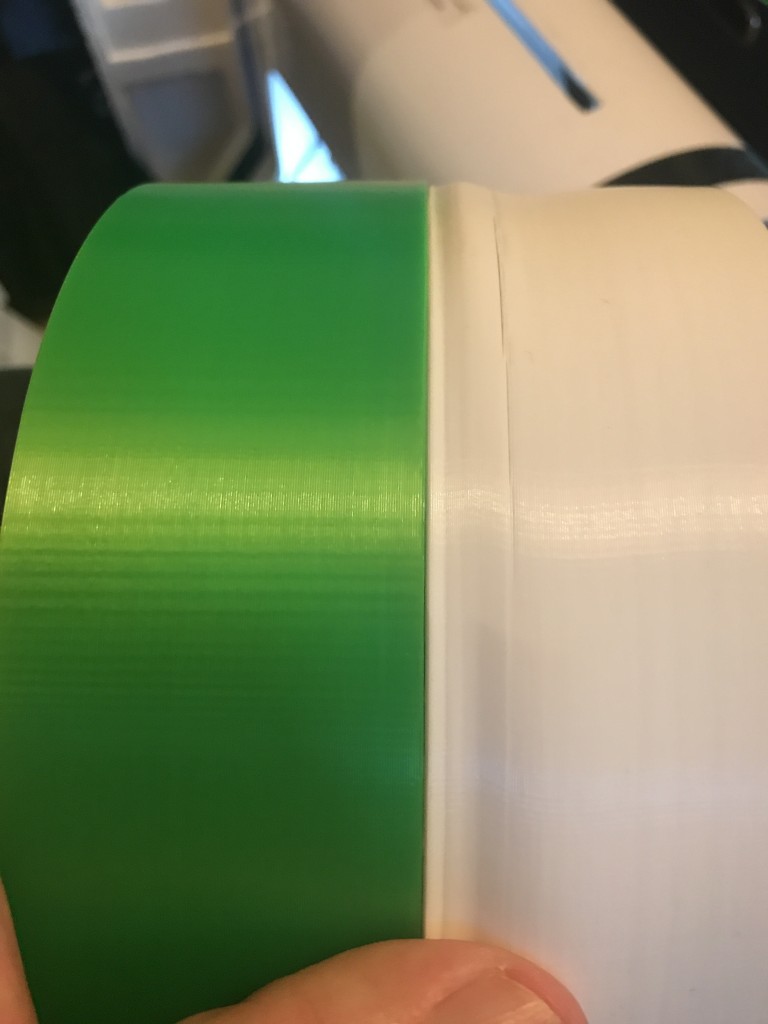

How well does it work? Well, the two prints here are printed with 1.1.9 and babysitting in white, and 2.0 with automatic control in green. So yeah, I think I’m happy!

Automatic fan speed control in green, manual control in white

Select Patreon subscribers get access to files a full 4 weeks before they’re released to the public.

The member page is publicly accessible here, but you’ll need a password to access the files. This password will change monthly and be made available to current Patreon subscribers. Thanks for your support!

I’m officially announcing my new Patreon channel. As part of the introduction all members will be given a specially designed rocket just for patrons! This is a limited time special so please sign up soon!

My design files will be posted for sponsors a month before the general public, as well as some limited edition designs just for subscribers.

The stack is progressing! In this issue I talk about the S-IVB stage and its transition to the lower airframe. More importantly I talk about an issue with the scale for the flyable version. Don’t forget to like and subscribe!

Below the CSM comes the SLA (Service Module to Lunar Module Adapter). In this video I discuss some basic printing tricks that can significantly reduce the amount of plastic used and time required to print. Don’t forget to like and subscribe!

For the most part, I’ve been a PLA guy. My goal was never to make 3D printing a hobby but to use it as a tool when making rockets. I’ve always had the intention of using ABS for a lot of reasons, but primarily due to the ventilation requirements I have only dabbled up to this point.

I can’t remember why I’d bought the PETG spool. It’s sat unopened for quite a while. From a rocketry point of view, it doesn’t like to be glued or painted so it’s not much use for a lot of what I wanted to do. At this point, I’ve been struggling with the Robo 3D for quite a while and it’s time to consider making my own. PETG is a good candidate for making the printed parts I need.

The first time I tried, I noticed that my old heater was worn out and tired. The project went on the back burner until I got that replaced. When that was done, I started on my Saturn V so that got placed on hold. Well, when I needed to print some test pieces for fit and size, my PLA was running low so it seemed like a good time to roll out my unused PETG.

My first impressions are good. PETG has a reputation for sticking so I put painters tape on my glass bed so there would be no damage. And stick it did. The downside is that I only have narrow tape, so the surface is uneven as it overlaps between strips. The large test pieces I printed came out great!

My next print was a reusable spool for filament purchased without the spools. Also great! I love the feel. The surface is smooth and it feels more like plastic than the rigid PLA prints do. Next was a spool holder for nylon (I’m getting adventurous now!) again with great results.

But back to PLA to print some pieces. And boy do they look like crap. I was blaming my printer with its known hardware issues. Then I looked at the PLA prints I’d just completed without the same issues and started to rethink things. Maybe it was the filament. You know the filament I’d bout 2 years previously that had spent half that time in storage and the other half idle on the spool holder. I printed the same part in PETG and I’m not blaming the printer anymore. It really is a shame you can’t glue or paint it!

As I write this my first spool of PETG is winding down, and I got a replacement supply of PLA today so it’s back to printing rocket parts. But PETG will have its place as well. If it can be screwed or fastened in other ways, like EBay sleds, and 3D printer parts, from here on out it will be PETG.

I still need to try the nylon, and I’m sure it will have its place, and ABS is definitely something I need to get back into. I’m now a multi-filament printer!